Our client, a government service provider, needed their own specialized products to deliver their services. They had outsourced the design to another firm but were dissatisfied with the resulting product’s performance. We inherited a typical turnaround situation, a design that was “complete and working except for…” In other words, it was not finished. Our job was to finish the existing design, and to move the product into full-rate production.

The most commonly overlooked and minimized phase of the development process is integration and test. Often, when non-engineers see a functional prototype, they think that the product is ready for mass production and the marketplace. The unfortunate truth is that the 80/20 rule (the last 20 percent of the functionality requires 80 percent of the effort) often applies at this point. Getting all the elements of the product to work together seamlessly as designed is the first challenge. After that, the product needs to be tested to the limits of its performance and environmental specifications. In this case, after evaluating and testing the product we inherited, we updated the design, tested and verified its performance, and moved it into production at a contract manufacturer.

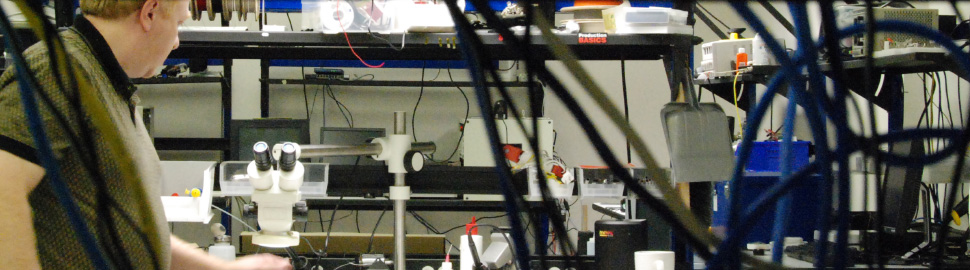

In preparation for volume manufacturing, we also developed a manufacturing test set to calibrate and verify performance as the units came off the manufacturing line. The manufacturing test contained a variety of pneumatics to inject a mix of normal atmospheric air and air containing a small calibrated concentration of alcohol. These unusual features were required in addition to the electronics and software typically incorporated into a test set for an electronic product. We created the test sets and trained the contract manufacturer on their operation. The most important part of this training was instruction on how to troubleshoot and rework units that failed the functional test.

We successfully moved the product into production at a contract manufacturer and are currently supporting bringing up a second contract manufacturer to accommodate our client’s growing volume production needs.

Whether it’s our design or one we inherit – getting products/projects finished is our specialty.