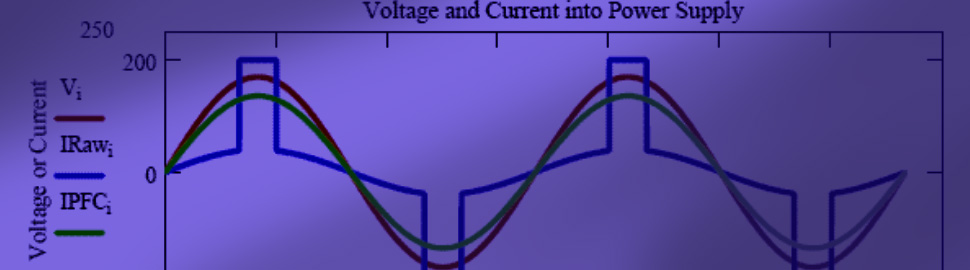

Some clients call upon us to design products to extend or support their primary product lines. These products can be simple line extensions or can be derivative products to support specific sales or market opportunities. An example of the latter case is the Power Factor Corrected Power Supply we designed for a client. Their product was designed to run off 48VDC but there were market opportunities where the primary power was 120VAC. Off-the-shelf power supplies were not acceptable due to the need for special operational features, a custom form factor, and regulatory requirements for power factor correction (keeping voltage and current waveforms closely matched).

Power-factor-correction is a key requirement in many modern power supply designs to assist power companies in managing the overall delivery of power across the grid. It makes power supply design considerably more complex, particularly at the lower power levels required in this case. In addition, the customer had several additional stringent requirements regarding:

- Turn on/off time

- Under-voltage and over-voltage limits

- Surge voltage protection

Of course, due to expected volume, low cost was also critical.

To meet this challenge, we first designed, developed and tested prototypes of the power supply to these demanding requirements. Next, the client successfully tested and qualified the prototypes. After customer acceptance, we then transitioned the power supply into production at the client’s high-volume contract manufacturer. The Power-Factor-Corrected Power Supply we developed substantially increased the client’s addressable market, while allowing their development team to concentrate on the next generation of their core products.